Coordinate Measuring Machine Accurately Detects Point T-Values, Easily Solving Glass Screen Measurement Challenges

Oct 23,2024 Author:lihejingmi Source:lihejingmi Visits:850

In the 3C electronics industry, quality and precision are core elements of the intelligent manufacturing concept. Only by accurately grasping the specific data of components while pursuing quality can the high quality from individual components to final products be ensured, and the glass used for 3C digital screens is no exception. Manufacturers of 3C products have also put forward higher requirements for glass screens in terms of improving quality, reducing costs, and increasing yield.

Customer measurement requirements

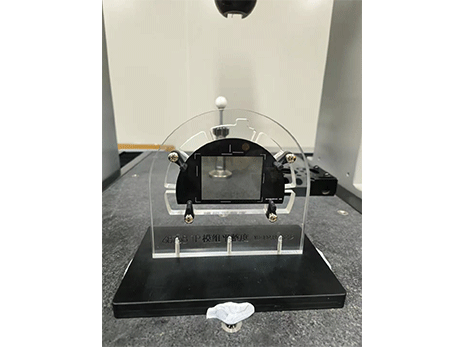

The customer needs a measurement solution that can not only accurately measure the T-values of glass screen points but also be applicable to the measurement of other surface forms of the product.

3C glass screen inspection solution

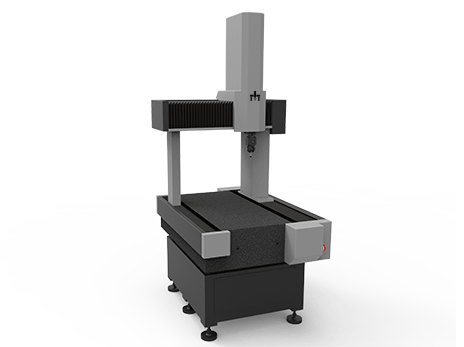

A Lihe Precision on-site linear guide coordinate measuring machine suitable for workshop inspection scenarios, paired with the CZ10T-S indexing probe holder, performs precise point collection on glass screens, doubling the inspection efficiency. Equipped with SuperDMIS measurement software, they form the "best partner" for measurement, providing customers with a comprehensive precision dimension inspection solution.

Measurement process

After fixing the glass screen on the workbench, the inspector uses the "plane-line-circle" method to establish a coordinate system, then inputs the point coordinates from the drawing, and uses the pre-set measurement program to control the probe movement for rapid collection of dimensional parameter data. Finally, SuperDMIS measurement software directly generates graphic reports, helping quality personnel intuitively and easily understand the quality of glass screen inspection and quickly take measures for unqualified workpiece quality issues.

Lihe Precision's 3C industry glass screen inspection solution can be widely used in the digital 3C industry. Relying on reliable hardware design and professional measurement software, it achieves efficient and accurate inspection, and can also be connected to automated production lines to provide data support for subsequent process improvement.

Relevant cases

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024