Efficiency Improved! Understanding the Three-coordinate Measurement of Mobile Phone Rear Cover Size

Oct 25,2024 Author:lihejingmi Source:lihejingmi Visits:853

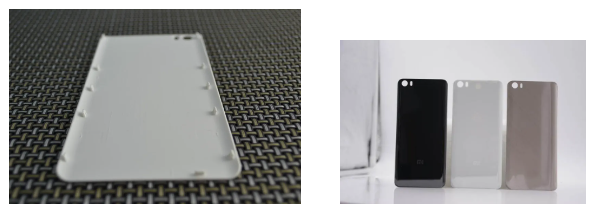

The production process of mobile phone covers is complex. Especially in the era of glass covers, more and more complex processes have been introduced, and the final customers' requirements for appearance are constantly increasing. Therefore, various characteristic defects such as dimensions are inevitably generated during the production process. In addition, during the process of mass inspection of mobile phone rear covers, labor costs and production efficiency are usually also the considerations of major manufacturers.

This puts forward higher requirements for the performance and measurement operation mode of high-end precision measuring instruments used to replace the traditional manual measurement of glass covers.

Full-process automation

Measuring mobile phone rear covers

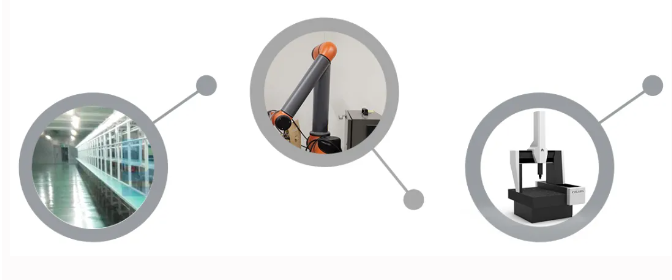

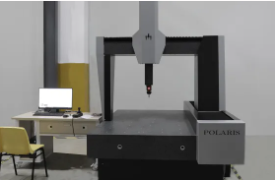

The R&D team of Lihe Precision has broken through technical barriers and changed the traditional measurement method of mobile phone parts, meeting the needs of manufacturers to improve production efficiency and save labor costs from the source. By placing an automatic robotic arm and a Lihe Precision moving-bridge coordinate measuring machine that can be matched with automatic loading and unloading next to the production line of mobile phone parts, and debugging the automatic measurement process settings such as movement, placement, scanning code, and measurement in advance, the continuity of work is ensured, thus realizing high-precision and high-speed automatic batch measurement operations of mobile phone rear covers.

Compared with the traditional manual measurement, the speed has been greatly improved, reducing the labor costs of mobile phone cover manufacturing enterprises and increasing the measurement efficiency by 20%.

Ensuring the accuracy of each geometric shape and

dimension of the mobile phone rear cover

The equipment applied to this automatic measurement scheme is a Lihe Precision high-precision moving-bridge coordinate measuring machine with an accuracy of up to 0.9μm verified by the National Metrology Institute. The high-rigidity four-sided enclosed air bearing guide design ensures the accuracy and long-term stability during the automatic measurement of mobile phone rear covers. Matching with the CZ10T-S indexing automatic probe holder, it efficiently completes the measurement of dimensional accuracy.

SuperDMIS

Supported by SuperDMIS high-precision geometric measurement software

SuperDMIS has a variety of coordinate system creation methods, which can quickly create an accurate 3D model of the mobile phone rear cover product, graphically display the dimensional errors of characteristic elements, and help mobile phone suppliers accurately control the quality of the measured parts.

The Lihe Precision moving-bridge coordinate measuring machine equipped with an automatic loading and unloading device can face the measurement challenges of mass parts such as mobile phone cases. It requires no manual intervention, has a high degree of automation, and significantly reduces labor costs. It is currently the most effective solution for high flexibility, high efficiency, and high precision measurement of parts such as mobile phone rear covers in the 3C digital industry.