Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025 Author:lihejingmi Source:lihejingmi Visits:1372

Generally, after the production of auto parts, manufacturers need to detect the parts to ensure the reliability of product quality. Auto parts are produced in large batches and have complex shapes, so higher dimensional accuracy is required for injection molded parts, which are key manufacturing components.

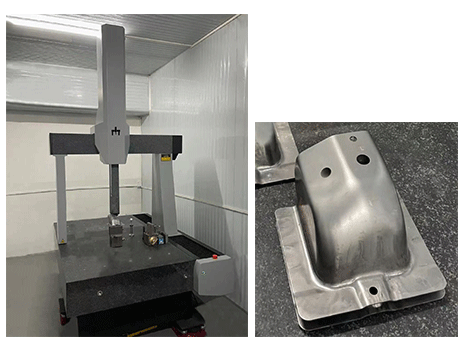

Given the shortcomings of traditional testing methods such as low accuracy, low efficiency, and poor stability of measurement results, Lihe Precision provides customers with optimal precision solutions by applying high-end precision coordinate measuring machines to production sites, effectively solving the inspection problems of injection molded auto parts.

Inspection Solution

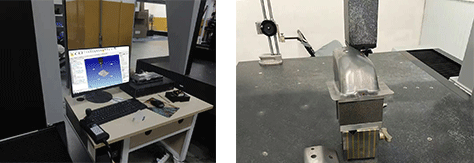

A classic moving-bridge coordinate measuring machine with high measurement speed and precision is used, paired with the CZ20i semi-automatic probe holder. The SuperDMIS software easily handles the measurement of parameters such as round holes and radians of injection molded auto parts, greatly improving measurement efficiency.

The CZ20i can achieve high-speed and high-precision positioning at 168 repeatable spatial positions, quickly collecting surface data required for measuring injection molded auto parts, and efficiently completing complex measurement tasks such as dimension, position, and shape of injection molded auto parts.

Inspection process and advantages

Fix the injection molded auto part on a fixture, then input the part parameters into the SuperDMIS measurement software to automatically generate and run the CMM measurement program. The SuperDMIS software can create an optimal inspection path, automatically scan and collect data, and complete data evaluation—no manual export is required. The entire process is convenient and fast, with stable and reliable data.

Relevant cases

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024