How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024 Author:lihejingmi Source:lihejingmi Visits:30276

In the mechanical manufacturing process, inspectors often need to check the position tolerance of hole groups. Without a comprehensive inspection tool, inspectors generally use vernier calipers for measurement, then determine whether the part is qualified through calculation and conversion. This operation is cumbersome, time-consuming and labor-intensive, and has a high probability of errors. However, using coordinate measuring machines (CMMs) ensures reliable precision, convenient operation, and high inspection efficiency.

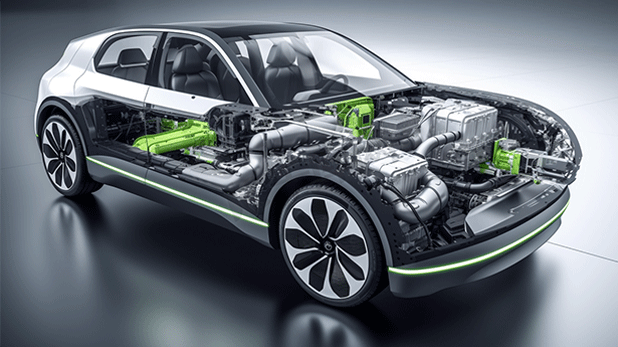

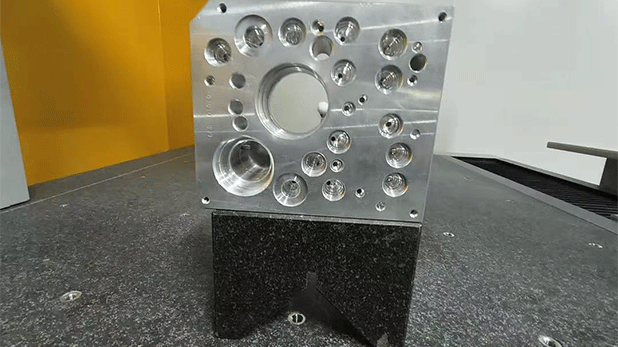

The hydraulic unit, which is one of the components of a new-energy automobile, plays a key role in the hydraulic system. To ensure product quality, manufacturers have high requirements for dimensional accuracy, and product dimensions must undergo precise measurement.

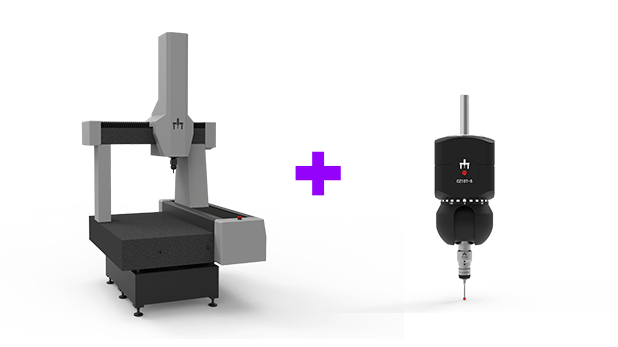

Measurement solution

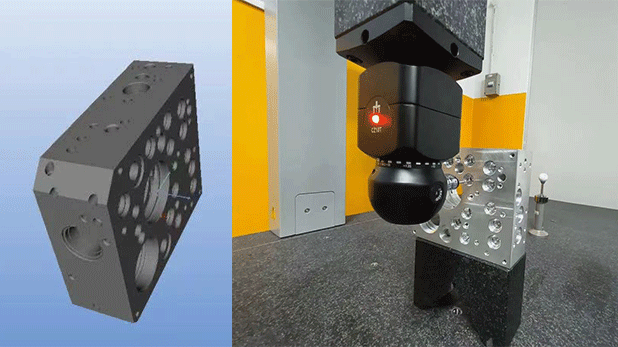

The hydraulic unit requires full-dimensional measurement, with approximately 300 dimensions, most of which are hole positions of various shapes, making inaccurate measurement likely. Therefore, customers are in urgent need of a solution to quickly solve the difficulties in hole position measurement. Lihe Precision's high-precision moving-bridge CMM, with excellent measurement accuracy, paired with the CZ10T indexing probe holder and different models of probes, can easily complete the high-precision measurement task of the hole positions of hydraulic units through software. Due to the varying sizes and depths of the holes, it is recommended to choose an automatic probe changer to make the entire measurement process smoother and save measurement time.

Measurement process

1. Fix the workpiece: Hydraulic units are relatively heavy and can be directly placed on the workbench for measurement. In addition, fixtures can be used for clamping, fixing, and heightening to prevent deformation and position movement during measurement.

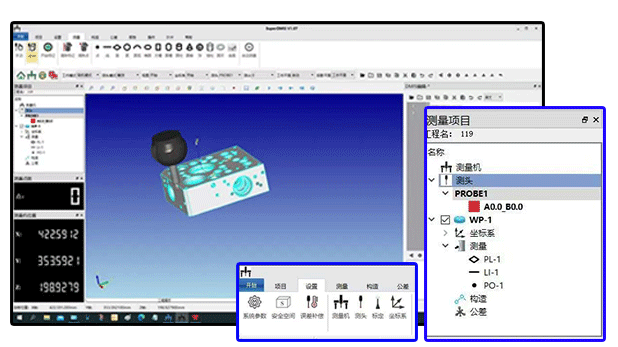

2. Establish a coordinate system and select the elements of the workpiece to be measured.

3. Control the probe and three-axis movement through a pre-set measurement program to quickly collect dimensional data of the hole positions.

4. After measurement, the measurement report can be directly saved on the SuperDMIS measurement software. QC personnel can intuitively and easily understand the product quality and quickly take measures for quality problems of defective products.

Relevant cases

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024