Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024 Author:lihejingmi Source:lihejingmi Visits:69211

Changzhou Jintan Dongfang Steam Turbine Fittings Factory has more than ten years of industry practice, whose main business is the manufacturing of blades, impellers and diaphragm assemblies for steam turbines, gas turbines, nuclear power, and aviation fields. Alone for blade products, the annual output reached 260,000 pieces in 2017. While coping with the increasing component demands from suppliers, Dongfang Steam Turbine Factory also pondered: How to control product quality faster and more accurately and deliver blade and impeller components on schedule?

High-precision and fast-measuring coordinate measuring technology was developed to "meet the challenge". It can quickly collect the dimensional parameters of the blade and impeller surfaces, and quickly generate intuitive graphic reports through measurement software. With a set of data in hand, you can comprehensively and effectively control product quality.

Solution

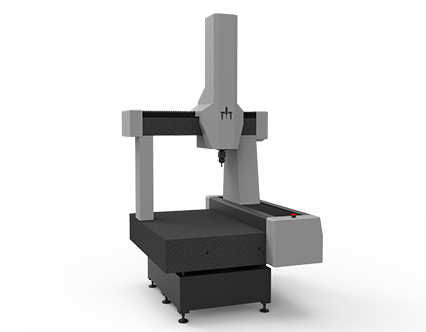

Dongfang Steam Turbine Fittings Factory addressed the inspection issues in blade and impeller manufacturing by adopting Lihe Precision's high-precision moving-bridge coordinate measuring machine, which integrates efficient measurement and high precision in one machine. Impellers usually require full-dimension inspection with many items; if single-point measurement is adopted, it will take a lot of time and cannot meet the efficiency requirements. Blade free-form surfaces are severely twisted, making interference highly likely during measurement.

The moving-bridge coordinate measuring machine, paired with the SC80 scanning probe with high error compensation performance, can perform continuous high-precision scanning measurement to achieve high-speed and high-precision sampling. Lihe Precision's Super DMIS software has a concise, intuitive and easy-to-understand interface; the measurement process is fast, convenient and efficient, and reports can be quickly generated after measurement.

Summary

Thanks to Lihe Precision's moving-bridge coordinate measuring machine with high measurement accuracy, the entire measurement process of blades and impellers becomes more effortless. When paired with the SC80 scanning probe and Super DMIS, it excellently solves the very complex profile measurement of impellers and blades.

Relevant cases

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024