Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024 Author:lihejingmi Source:lihejingmi Visits:557908

Orthopedic implants are one of the most important categories of orthopedic medical devices. The dental implants, spinal implants and hip joint implants for human body that we often hear about in daily life all belong to orthopedic implants. In the processing of orthopedic implants, medical device manufacturers often face dual challenges of processing cycle and quality. In the inspection link, Lihe Precision can safeguard the product quality and production cycle of medical device manufacturers through the high-precision coordinate measurement technology of coordinate measuring machines. The following takes the measurement of the dimensions of spinal implants and human hip joint implants as examples.

Measurement Scheme

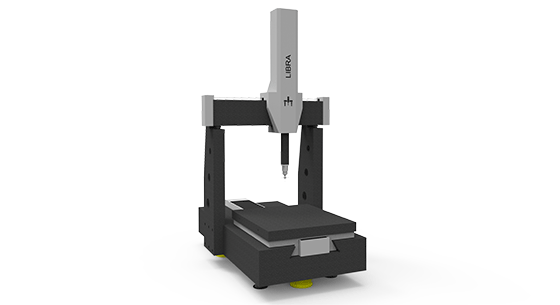

Lihe Precision's fixed-bridge coordinate measuring machine has an accuracy of up to 0.6μm. The entire machine is made of high-rigidity granite material and is equipped with fully independently developed components. It can efficiently capture and measure multiple measurement points, easily completing the measurement tasks of precision components such as spinal implants and human hip joint implants.

Measurement process

Such precision parts are usually made of titanium alloy, with small size and complex shape. They require multi-angle measurement and have requirements for the accuracy and diversity of the finally output measurement data report. If the measurement results and accuracy fail to meet the design requirements, the performance and use effect will be affected.

Solution advantages

This solution only needs to set up programming in advance. After operation, it can accurately and quickly measure all required dimensions of the product at one time, and can solve the problem that traditional equipment is difficult to meet the requirement of one-time measurement. It can perfectly output measurement data reports, facilitating quality personnel to sort out defective implants before further processing, thus shortening your processing cycle.

Lihe Precision's high-precision moving-bridge coordinate measuring machine, paired with the SC80 scanning probe, provides a high-precision and high-efficiency measurement solution for orthopedic implants. It helps medical device manufacturers implement production details, accurately inspect every component, ensure product quality management, and safeguard the subsequent use of products.

Relevant cases

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024