Application of Coordinate Measuring Machines in the Inspection of Compressor Scroll Plates

Mar 06,2024 Author:lihejingmi Source:lihejingmi Visits:915

The scroll air compressor is a new type of high-efficiency and environmentally friendly equipment, and a key component leading the development trend of the new wind energy industry. It mainly uses the relative orbital revolution of the movable and fixed scroll plates to form continuous changes in the closed volume, thereby achieving the purpose of compressing gas.

Its compression components consist of a movable scroll plate and a fixed scroll plate, which have the advantages of high efficiency, low noise, and small size. However, due to the curved surface of the scroll plate, which is an involute spiral, both processing and inspection are relatively complex, and traditional inspection methods cannot meet the measurement needs of manufacturers.

Inspection Solution

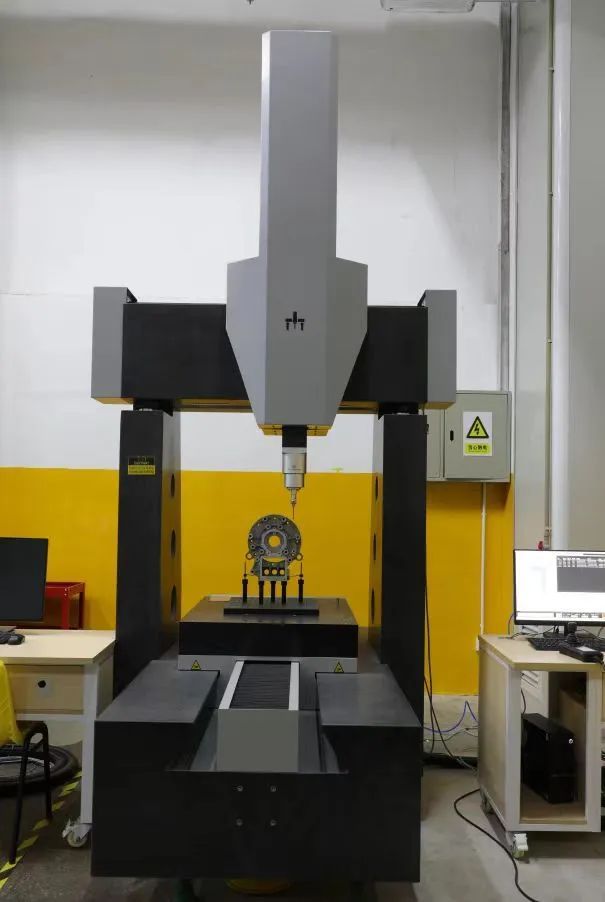

To address the above issues, Lihe Precision has designed a fast and effective measurement solution specifically for compressor scroll plates. Lihe Precision's fixed-bridge ultra-high-precision coordinate measuring machine adopts continuous scanning technology, enabling high-precision continuous operation, and is suitable for the inspection of complex curved surfaces such as precision shafts and gears. Equipped with the professional measurement software SuperDMIS, it helps enterprises efficiently complete the measurement tasks of complex curved workpieces such as scrolls.

The SC80 scanning probe and SuperDMIS measurement software are selected for measurement. The SC80 scanning probe supports uninterrupted continuous scanning function, which can meet the inspection and reverse engineering requirements of parts with complex surfaces such as curves and curved surfaces. With the coordination of software and hardware, Lihe Precision's fixed-bridge ultra-high-precision coordinate measuring machine can efficiently complete measurement tasks.

Inspection Solution

Fixture clamping

Improper support can lead to measurement errors. Therefore, when measuring scroll compressors, special fixtures are used for support, and external forces that may cause workpiece deformation should be avoided to ensure the credibility of the inspection data.

Coordinate system establishment

To meet the high-precision requirements, the best-fitting method can be adopted to establish the coordinate system quickly and conveniently.

Profile degree measurement

The inspection requirements for scrolls are very strict. To achieve the goal of accurate and efficient inspection, after establishing the reference coordinate system, measurement software is used for profile degree inspection and analysis.

Profile degree analysis

Tolerance → Curve profile degree → Set corresponding parameters → Calculate profile degree and save the graph to the report.

Precision part manufacturing cannot do without the guarantee of precision measurement. Scroll inspection is a technical guarantee for quality control in the manufacturing process and an important basis for finished product acceptance. Lihe Precision's fixed-bridge ultra-high-precision coordinate measuring machine, combined with measurement software, can help users produce high-quality components such as scroll plates, further improve product performance, and thus bring more economic and social benefits to users.

Precision part manufacturing cannot do without the guarantee of precision measurement. Scroll inspection is a technical guarantee for quality control in the manufacturing process and an important basis for finished product acceptance. Lihe Precision's fixed-bridge ultra-high-precision coordinate measuring machine, combined with measurement software, can help users produce high-quality components such as scroll plates, further improve product performance, and thus bring more economic and social benefits to users.

Hot Articles

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024