What Can a Coordinate Measuring Machine Measure?

Mar 06,2024 Author:lihejingmi Source:lihejingmi Visits:913

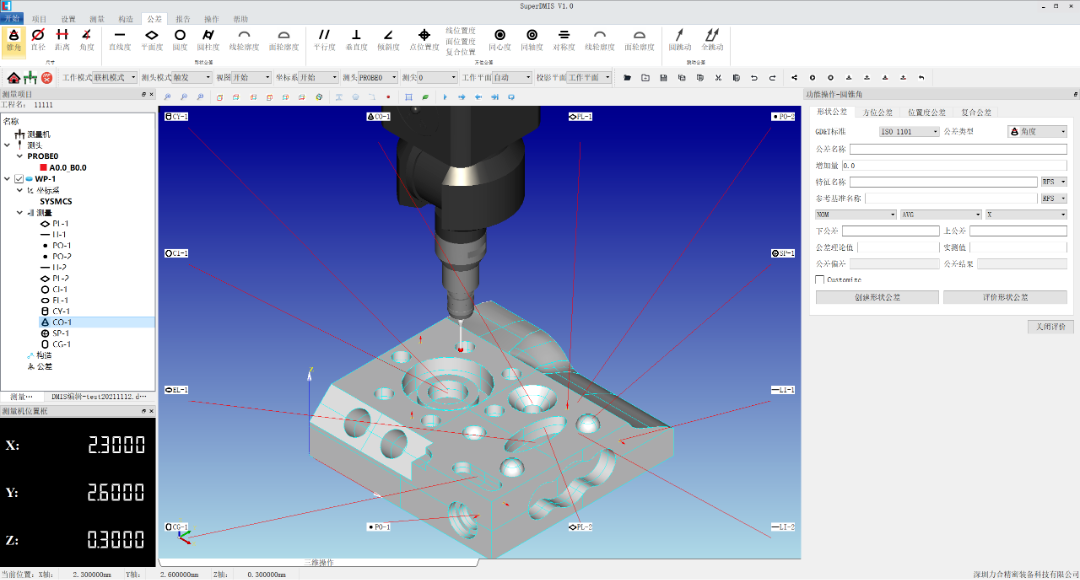

1. Geometric tolerances mainly inspected by coordinate measuring machines

Measurement of geometric elements:Points, lines, circles, planes, spheres, arcs, ellipses, cylinders, cones, keyways, curves, surfaces.

Construction of geometric elements:Projection, bisection, intersection, tangency, mirroring, fitting, translation, perpendicularity, parallelism, combination, rotation, offset line, offset.

Geometric tolerance software:Straightness, flatness, circularity, cylindricity, conicity, sphericity, distance, included angle, perpendicularity, parallelism, angularity, positional tolerance (2D and 3D), symmetry, coaxiality, concentricity, runout, etc.

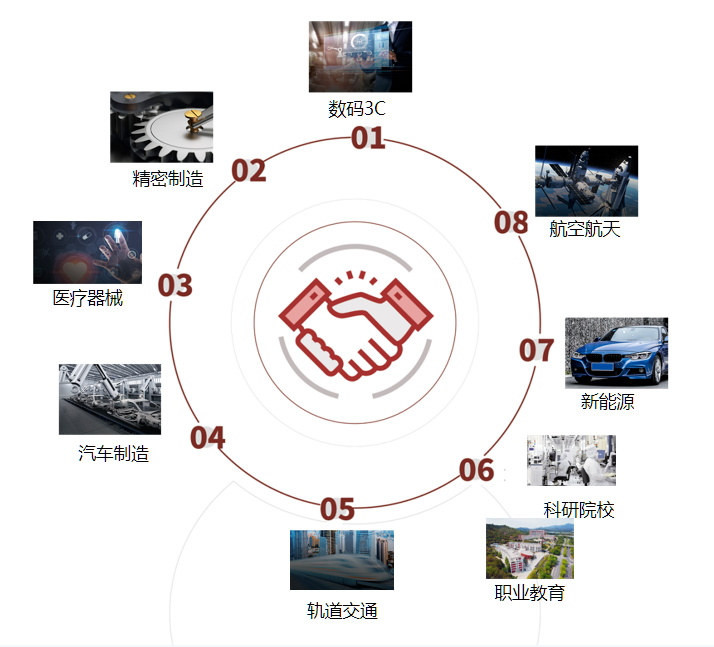

2. Application scenarios of coordinate measuring machines

Coordinate measuring machines are currently widely used in aerospace, military industry, research institutes, digital 3C, mold manufacturing, automobile, rail transit, medical equipment, new energy and other industries.

They can perform precision inspection of workpiece dimensions, shapes, and geometric tolerances. For example, they can be used to measure boxes, frames, gears, cams, worms, worm wheels, blades, curves, surfaces, etc., thereby completing tasks such as part inspection, shape measurement, and process control.

(Digital 3C/Precision Manufacturing/Medical Devices/Automobile Manufacturing/Rail Transit/Vocational Education/Scientific Research Institutions/New Energy/Aerospace)

Hot Articles

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

How to easily tackle the difficulties in shaft part measurement?

Oct 25,2024

-

Application of Coordinate Measuring Machine: Measuring Dimensional Accuracy of Orthopedic Implants

Oct 24,2024

-

The vehicle light detection scheme of Lihe Precision's classic moving-bridge coordinate measuring machine

Oct 22,2024

-

How to precisely measure the hole positions of the hydraulic transmission unit of an automobile?

Oct 22,2024

-

Coordinate Measuring Machine Accurately Measures the Dimensional Accuracy of Blades and Impellers

Oct 21,2024