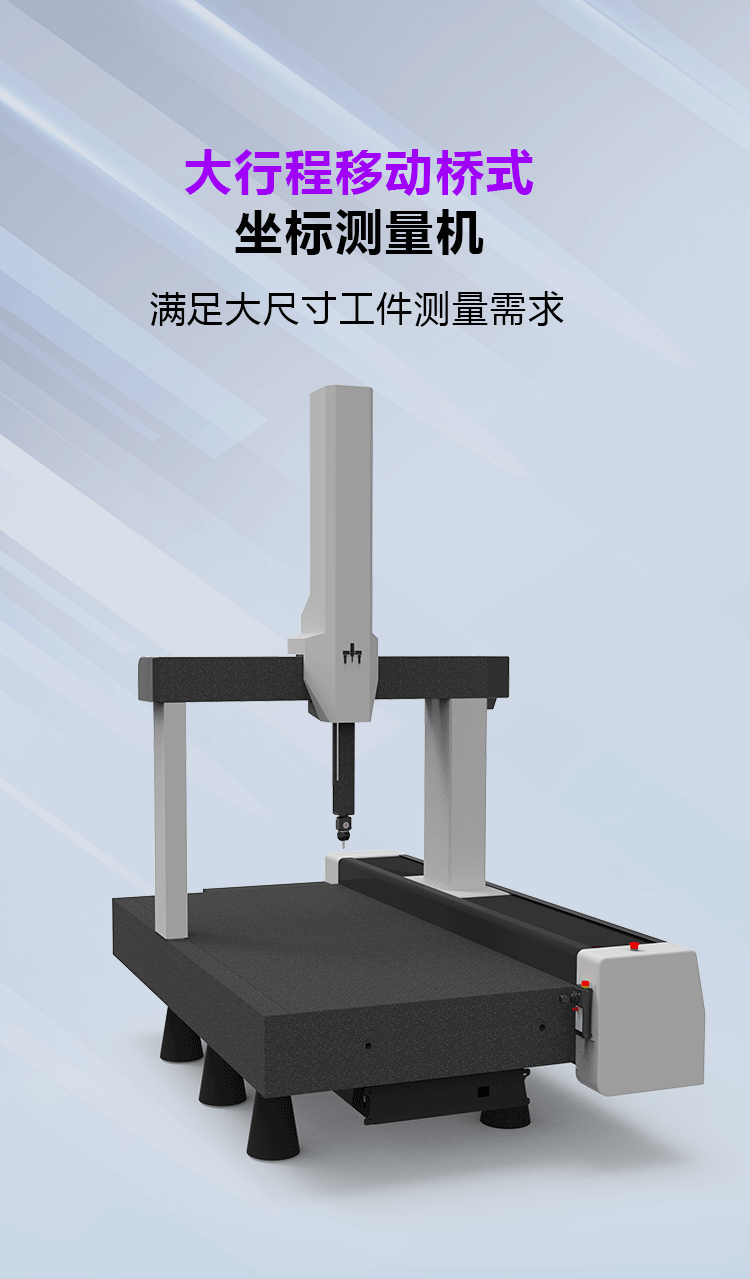

Large-Travel Moving-Bridge Coordinate Measuring Machine: Integrating Open Measurement Space + Super Large Load-Bearing Capacity

Jan 13,2025 Author:lihejingmi Source:lihejingmi Visits:1653

Lihe Precision's large-travel moving-bridge coordinate measuring machine adopts new mechanical design technology and advanced material technology to provide customers with excellent high precision and dynamic performance. The maximum measurement travel can reach 1500mm×3000mm×1200mm, which can meet the measurement needs of large-size workpieces.

Equipment features

1. It has an open measurement space and excellent table load-bearing capacity, providing reliable measurement support for medium and large workpieces.

2. The left column is made of high-strength carbon fiber material, which has good stability, deformation resistance and excellent rigidity, ensuring the dynamic measurement accuracy of the measuring machine.

3. The sturdy and high-stability imported granite worktable has strong load-bearing capacity and small deformation, ensuring the stability and reliability of the measuring machine.

4. According to the structural characteristics of large travel, a gapless steel wire flat belt is designed, which combines the advantages of small tensile deformation and high axial transmission rigidity, ensuring good transmission performance of the machine.

5. The worktable can be customized according to the weight of the workpiece, with flexible adaptation of load-bearing capacity.

6. Different vibration isolation systems can be selected according to different environments to adapt to special and complex testing environments.

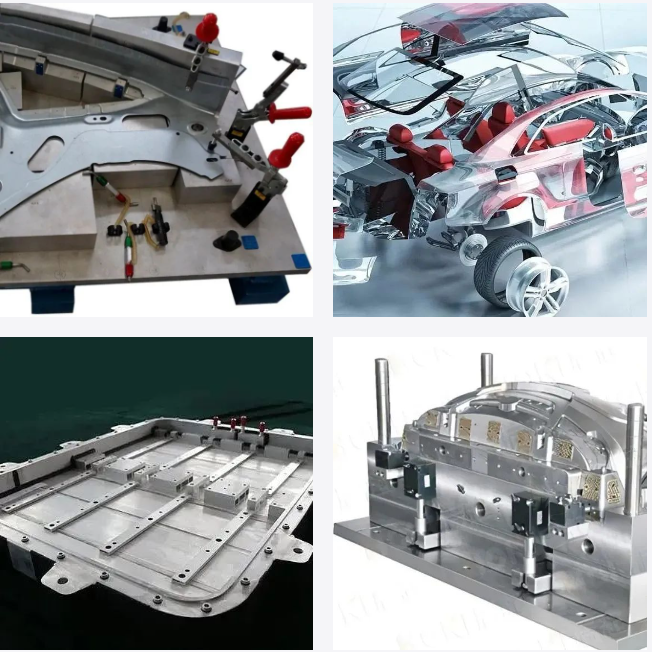

Application scenarios

Due to its high precision and reliability, the large-travel moving-bridge coordinate measuring machine is widely used in various industries such as machinery manufacturing, automobile, aerospace, electronic equipment, and mold making. This coordinate measuring machine can accurately inspect the dimensions, shapes, and geometric tolerances of workpieces such as large inspection tools, large jigs, auto parts, and battery trays. It ensures the efficient completion of key tasks such as part quality control, shape measurement, and process control, thereby improving the overall product quality and production efficiency.

Product Parameters

Product model: Starting from 10128

Travel: X-axis 1000mm; Y-axis 1200mm; Z-axis 800mm

MPEe:1.4+L/300起

MPEp:2μm

Temperature range: 18°C~22°C

Temperature gradient: 1℃/h - 2℃/24h, 1℃/m

Humidity: 40-70%

Voltage: 220V±10%

Current: 15A

Air supply pressure: 6 bar [0.6MPa]

Air consumption: 120NL/min

Maximum load capacity: 3000 kg

Vibration: When frequency ≤10Hz, amplitude ≤1μm; when frequency >10Hz, amplitude ≤20μm

Hot Articles

-

Three-coordinate Detection of Auto Parts Injection Molds

Sep 15,2025

-

Customer case: How does a large-stroke moving-bridge coordinate measuring machine efficiently measure large machine tool beds?

Oct 21,2024

-

Efficiency Improved! Understanding the Three-coordinate Measurement of Mobile Phone Rear Cover Size

Oct 25,2024