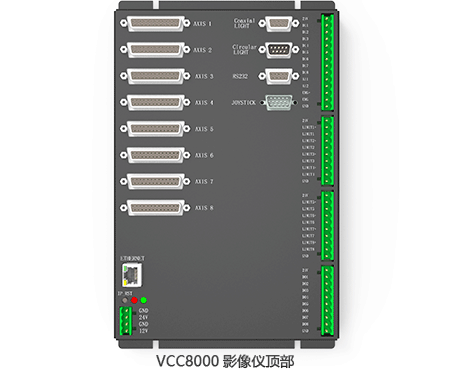

VCC series high-precision image measurement controller

The VCC series features functions such as full-closed-loop motion control, 3D linear interpolation, 3D spatial circular interpolation motion, and multi-point continuous motion, enabling flexible and efficient motion control with high positioning accuracy and fast speed. It is ideal for coordinate and image measuring systems. Models VCC4500 and VCC8000 further support advanced features such as on-the-fly image capture, automatic probe headss, and TP20/TP200 probe measurement.

- Product model: VCC3200、VCC4500、VCC4800、VCC8000

1. Compact structure design.

2. Full closed-loop position control for precise structural end-position management.

3. 3D spatial interpolation ensuring smooth, stable motion.

4. High-speed position capture for precise probe-triggered measurements.

5. Real-time feed-rate adjustment during motion.

6. 100M Ethernet communication with low latency and stable performance.

7. S-curve acceleration/deceleration to minimize vibration.

8. Ergonomic manual controller for intuitive and durable operation.

Product Parameters

Parameter Name | VCC3100 | VCC3200 | VCC4500 | VCC4800 | VCC8000 |

Input voltage | DC24±2V/3A | DC24~48V/10A | DC24~48V/10A | DC24V/2.5A | DC24~48V/10A |

Supported axes | 4(XYZU) | 4(XYZU) | 4(XYZU) | 4(XYZU) | 8 axes |

U-axis drive mode | Built-in stepper drive/ Pulse + Direction (open-loop control) | Built-in stepper drive/ Pulse + Direction (open-loop control) | Pulse + Direction (open-loop control) | Pulse + Direction (open-loop control) | N/A |

Closed-loop control algorithm | PID+VFF | PID+VFF | PID+VFF | PID+VFF | PID+VFF |

Servo refresh frequency | 200us | 200us | 200us | 200us | 200us |

Maximum pulse output frequency | 4MHz | 4MHz | 4MHz | 4MHz | 4MHz |

Chassis dimensions | 263*134*59.1mm | 263*134*59.1mm | 294*123*59mm | 294*138*66mm | 270*170*25mm |

Linear scale count axes | 3(XYZ) | 3(XYZ) | 4(XYZU) | 4(XYZU) | 8 |

Linear scale signal type | Single-ended or differential | RS422 differential signal | RS422 differential signal | RS422 differential signal | RS422 differential signal |

Linear scale maximum count frequency | 5MHz | 20MHz | 20MHz | 20MHz | 20MHz |

LED drive channels | 11 channels (8+2+1) | 11 channels (8+2+1) | 11 channels (8+2+1) | N/A | 11 channels (8+2+1) |

Surface light drive capacity | 8 zones: 150mA(max)@24V/channel constant current; serial control for up to 40 zones | 8 zones: 30mA(max) @24V/channel constant current; serial control for up to 40 zones | 8 zones: 100mA(max)@24V/channel constant current; serial control for up to 40 zones | serial control for up to 40 zones | 8 zones: 100mA(max)@24V/channel constant current; serial control for up to 40 zones |

Contour light output capacity | 150mA@5V or 1500mA@12V | 50mA@5V or 400mA@12V constant current | 50mA@5V or 400mA@12V constant current | N/A | 50mA@5V or 400mA@12V constant current |

Coaxial light output capacity | 1500mA@5V | 150mA@5V constant current | 150mA@5V constant current | N/A | 150mA@5V constant current |

I/O extension | 8 Input/8 Output (24V) | 8 Input/8 Output (12V or 24V) | 8 Input/8 Output (24V) | 17 Input/16 Output (24V) | 8 Input/8 Output (24V) |

Communication mode | 100M Ethernet | 100M Ethernet | 100M Ethernet | 100M Ethernet | 100M Ethernet |

Probe head support | Manual/semi-automatic probe holders such as MCP, PH6 | Manual/semi-automatic probe holders such as MCP, PH6; automatic probe holders PH10T/M, CZ10T | Manual/semi-automatic probe holders such as MCP, PH6; automatic probe holders PH10T/M, CZ10T | Manual/semi-automatic probe holders such as MCP, PH6; automatic probe holders PH10T/M, CZ10T | Manual/semi-automatic probe holders such as MCP, PH6; automatic probe holders PH10T/M, CZ10T |

Probe support | TP20、CF20 | TP20、CF20 | TP20、CF20、TP200 | CF20、TP20、 TP200、CF30 | TP20、CF20 |

Flying photography function | N/A | N/A | Supported | Supported | Supported |

Error compensation function | Single-axis linearity + perpendicularity compensation | Single-axis linearity + perpendicularity compensation | 21 mechanical error compensations | 21 mechanical error compensations | 21 mechanical error compensations |

Adaptable Accessories

Document Download